NOV (National Oilwell Vacro) is a global company in the fields of drilling and conveying technology. NOV supports the world’s most advanced drilling solutions in the oil and gas industry.

Here almost 150 measuring channels are used in a test system:

- 10 x IEPE with 5 x Q.bloxx A101

- 24 x current with 3 x Q.bloxx A108

- 12 x Pt100 with 3 x Q.bloxx A107

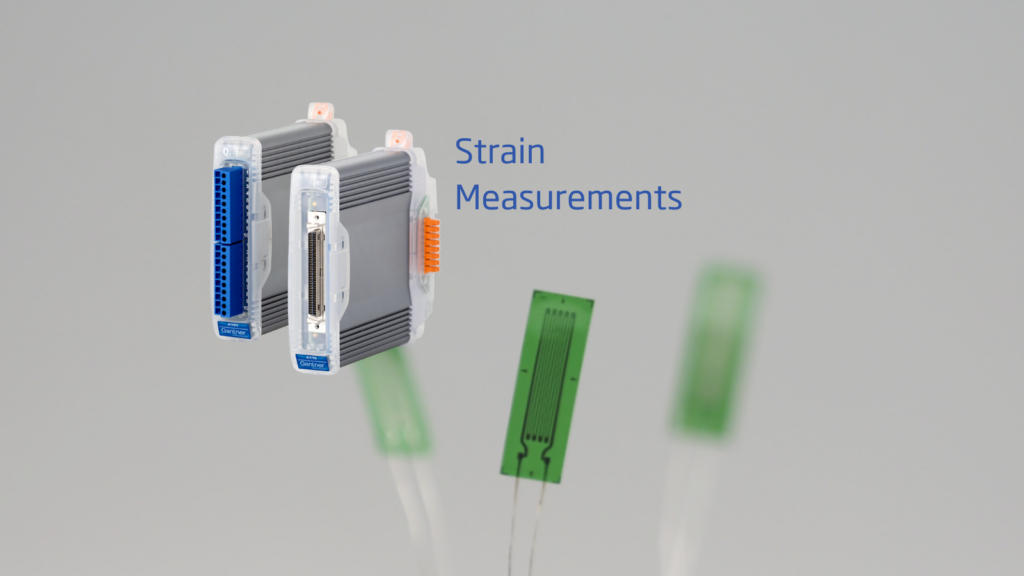

- 96 x SG with 12 x Q.bloxx A116

- Multiple digital I/Os

The measured data is recorded at a sample rate of 10 kHz. A data logger was configured in the Q.station test controller that records the conditioned and raw data. The recorded data is transferred to a SQL database using the test.node server software.

At present, four test systems are being built; with additional systems being planned. Testing is performed in cooperation with our Danish partner IPC Teknik ApS.

More articles

Gantner Instruments appoints Bienfait as new Business Partner in the Netherlands

Gantner Instruments is pleased to announce that is has appointed Bienfait B.V. as business partner in the Netherlands. Bienfait will support Gantner Instruments’ entire portfolio of test and measurement solutions. The appointment provides stronger local support for the country’s rapid growth in key sectors like high-tech systems, energy, water and advanced composite materials.

Read more...Q.series interface with the Moog Aerospace Test Controller

The amount of data generated in an aircraft structural test program continues to grow. The density of load introduction points (actuators) and sensors (strain gauges, thermocouples, LVDTs) on a test article is increasing progressively and model validation requires higher data sample rates to capture more detail. The risks and costs involved in aircraft validation and certification are significant, and the requirement for quick entry-into-service is high. To minimize the impact of retrofitting in-service aircrafts, the ability to generate test results quickly is crucial to the success of a test program.

Read more...Measurements at -40°C ambient temperature

We just tested our Q.bloxx XL A104 TCK in the climate chamber at -40°C ambient temperature and it does a perfect job under these extreme conditions.

Read more...Test Like You Fly, Fly Like You Test

When building a rocket there is a whole flight certification process, and qualification is an important part of that. It proves the hardware meets the requirements and performs the way it is designed to do. Of all parts of a rocket, the engine section is perhaps the most critical during launch. The weight of the massive rocket is pushing down, while the engines are pushing up with millions of pounds of thrust. Whether it is an engine for experimental rockets or for commercial spaceflight, adequate testing is critical to the success of each launch program.

Read more...