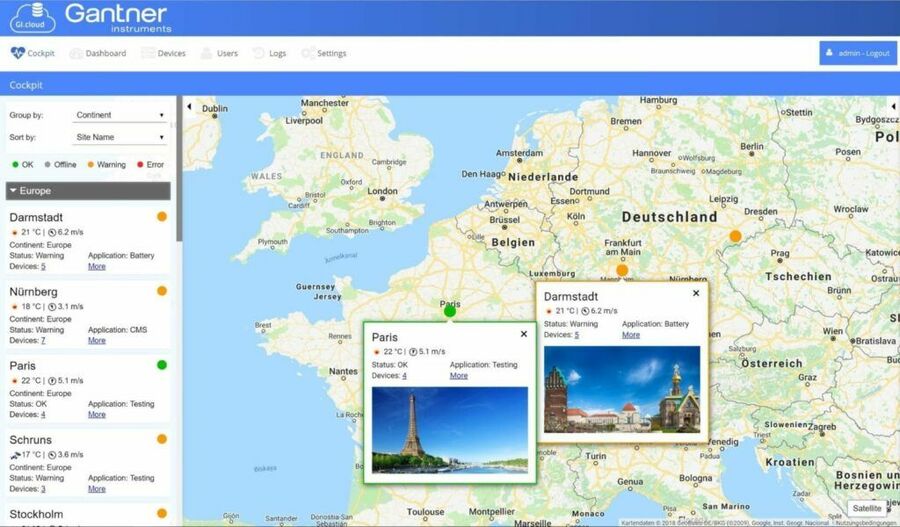

GI.cloud is an innovative platform that combines Gantner Instruments’s proven edge-type monitoring and control units. An adaptive cloud system with a comprehensive user interface and applications with state of the art APIs. All these combined, allow the user to acquire data and read information about their assets in real-time from a remote location.

GI.cloud cockpit

The flexible configuration of GI.cloud allows customers to build the system exactly to their needs and also protects their investment: once the powerful edge and scalable cloud modules are installed, together with customizable service plug-ins, they will allow meeting higher demands in the future.

GI.cloud benefits

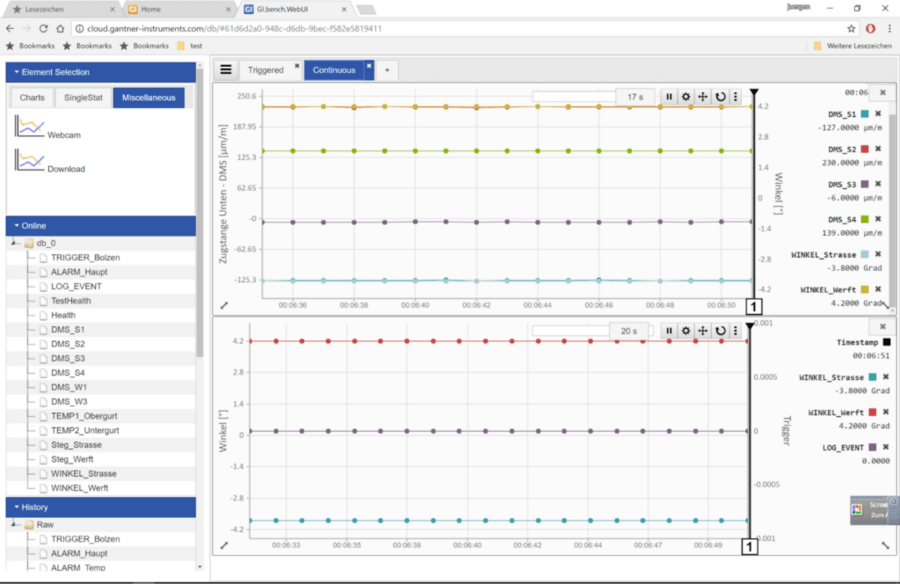

- Customizable user interfaces with easy plug-in and feature add-on

- Create your own dashboard for visualization

- APIs designed for fast integration into the customer’s platform and data access

- Efficient time series data processing (down to microseconds) due to a scalable platform

- Unlimited data storage on the device or based on a scalable data stream processing platform (granularity: microsecond to minutes)

- Continuous integration of GI.bench services and configurations to cloud level

- Available platforms: cloud, appliance or desktop

- And more ……

With GI.cloud our customers can adapt to increased data acquisition speed, data management, and analytics requirements. To learn more about this product click here.

More articles

6 Tips for Stress-free Strain Measurement during Fatigue Testing of Aircraft Structures

Strain is the single most important measurement during aircraft fatigue testing. The accuracy and precision of strain gauge measurements is of the greatest importance to exactly determine the durability and damage tolerance of a structure. The higher a structure is in the ‘pyramid of test’, the higher the test complexity, number of measurement channels, and data produced. On top of that the risk in terms of time delay and cost associated to a test program increases more than proportional with the increase in test complexity. Here are six tips to help you choose the right data acquisition system for your fatigue test:

Read more...Career Fair Germany 2024

Join us on Tuesday, May 14, 2024, from 10 AM to 5 PM at the Meistersingerhalle, Nuremberg at the career fair. Visit our booth to explore a world of career opportunities in industrial measurement technology.

Read more...Force monitoring improves efficiency of Airbus’ Final Assembly Line

In November 2016 the Airbus A350-1000 flew for the very first time. The A350-1000 is part of the A350 XWB family and is Airbus’ largest and most powerful twin-engined airliner ever. Airbus began the assembly of the A350-1000 in September, 2015, less than a year after the first delivery of the A350-900. For maximum flexibility, the existing A350 XWB Final Assembly Line (FAL) can be used for both A350-900 and A350-1000 models.

Read more...The A136 Strain Gage Amplifier: Redefining Precision Measurement

The new I/O module for 1kOhm strain gages and semiconductor-based sensors that require 10V excitation.

Read more...