Magnets mounted on the track, which are used for the “train protection system” (PZB) and whose exact position is known, are detected during the measurement process to equalize inaccuracies in kilometer measurement. During measurement, vehicle-mounted optical sensors scan both sides of the rail tracks to detect elevated objects. They required a system that filtered out the PZB magnet from the field of observation. The information whether a PZB magnet is in close proximity needed to be available via a digital output. In addition, the status of the digital inputs and outputs had to be transmitted via a network interface to the control system.

Realisazation

The Q.raxx system and the Q.station test controller from Gantner Instruments were chosen as the platform for the implementation.

To save space the system can be installed in an existing 19-inch rack and provides twelve slots for measurement or I/O plug-in boards. The D101 digital metering unit has eight isolated digital inputs and an equal number of digital outputs. The free slots allow for easy expansion for future measurement tasks.

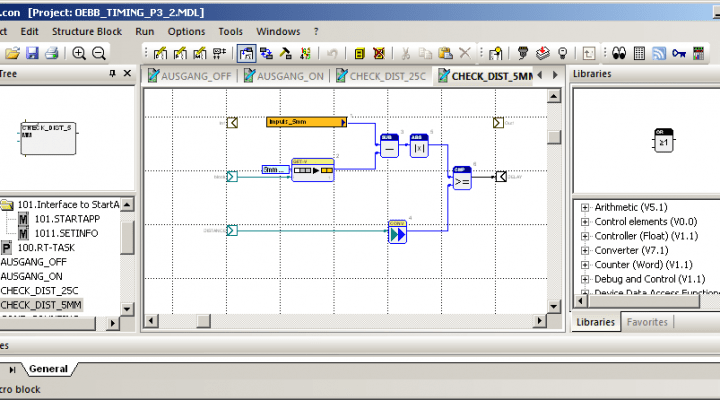

Programming of the controller was accomplished using the graphical programming tool of the test.con programming system. The combination of flow charts and macros makes the code easy to read.

Thanks to the real-time processing capability of Q.station with 10 kHz, the PZB magnets could be reliably detected even at measuring speeds up to 230 km per hour.

In addition, the Q.station test controller provides the control system with all relevant data via Ethernet interface. The values of the four sensors are sampled every 5 mm (!), recorded, compressed, and transmitted in IP packets to the control system.

The position of PZB magnets is correlated with measurement data from the measurement vehicle by means of Green-Eye analysis software from Aplica. Green-Eye provides a clear and flexible user interface for the display, analysis and storage of all measurement data.

More articles

Battery Cell Testing in the Automotive Industry

The automotive industry is undergoing a transformative shift toward electric vehicles (EVs), making battery technology a central focus for innovation. As consumer demand for EVs grows, reliable battery performance and safety have become more critical than ever. At the heart of guaranteeing reliability is thorough, methodical battery cell testing. Below, we explore why cell testing is so vital, how it’s done, and the key challenges in today’s market.

Read more...Introducing License Flexibility: GI.bench’s Latest Update Adds Dongle Support

We are excited to announce the newest enhancement to GI.bench. With the introduction of License-Dongle support and several minor improvements, GI.bench continues to evolve with functionality that anticipates and meets the evolving needs of professionals in the field.

Read more...Airbus has selected the Q.raxx EC with EtherCAT interface as the integrated control and measurement solution for their component structural testing lab

Airbus Helicopters is a world-leading designer and manufacturer of helicopters. The company’s product line offers the full spectrum of rotary-wing aircraft solutions for civil, government, military, law enforcement and parapublic uses. With the growth in business and innovation of their product offering, Airbus Helicopters decided to modernize their structural test facility at their main facility in Donauwörth, Germany.

Read more...Monitoring Solutions for Asset Management

Gantner Instruments provides monitoring solutions for both static and dynamic equipment in terms of vibration monitoring of piping, vessels, heat exchanger, large machines (static) and pumps, fans, and turbines (dynamic). Based on the robust and flexible Q.series modules with its decentralized signal conditioning and data acquisition modules, a very reliable and cost effective trend and condition monitoring solution is available and working also under harsh environmental conditions. With the monitoring solution of Gantner Instruments the asset becomes smart and delivers detailed status information.

Read more...